H3C's Intelligent Cabinet Solution for Financial Services

Requirement analysis

Construction trends of data center

Green power: According to statistics, the total power consumption of data centers all over the world has accounted for 3% of the global power consumption at present. In 2016 and 2018, three ministries including the Ministry of Industry and Information Technology of the People's Republic of China have jointly issued documents twice, requiring governments and state-owned enterprises to feasibly implement the energy conservation requirements for data centers and to reduce energy consumption of data centers. According to statistics from relevant units, electric charges of data centers in China account for 60%-70% of the total O&M costs of data centers. The electric charges for 4 years of one full-load data center are sufficient to build one data center of the same scale. Therefore, energy conservation is the demand for cost and also the demand for social responsibility.

Modularization: Data centers are important carriers that serve the development of the national digital economy and support the strategic layout of a new generation of information technology. Especially, after computing fully permeates from clouds to edges, data centers become key points in deciding application experiences and service quality. Under the new situation, the way to transform data centers to achieve shorter cycles, better energy conservation and environment protection and high economic benefits are of top priority. With the development of technology, especially the development of precision air conditioners in equipment rooms and UPS technology, construction of data centers evolves into modularization and miniaturization. The features of modular data centers include one-time planning, deployment by stages, prefabrication, field assembly and flexible expansion. In addition, as edge computing booms, small and medium-sized modular data centers certainly will become rigid demands.

Digitalization: The digital times drive the great development of data centers. However, digital applications planned and constructed for data centers are extremely outdated. By virtue of technologies such as BIM, data centers can be disassembled into tens of thousands of digital members. Digital technologies are applied to the full life-cycle of data centers from consultation, design, construction to O&M, greatly improving quality, reliability and O&M level of data centers.

Integration: Integration of infrastructure and ICT basic architecture becomes a trend. Monitoring and management of infrastructure cannot be separated from ICT monitoring. Customers cannot afford crashes incurred by failures of infrastructure, and are unwilling to accept two O&M management systems and evaluation modes that are completely different from each other. To sum up, the integration of infrastructure and ICT basic architecture management becomes an inevitable trend.

Analysis on customer’s pain points

No uniformly planned standard architecture

No unified construction guide and recommendations and hard to ensure product form

Diverse product models and difficult-to-implement centralized management by stages

Long procurement and deployment period and high initial investment

Different planning, design and construction providers and existence of connection problem

Large construction scale, high initial investment and huge financial and capital pressure on owners

Low intelligent management level and complicated local maintenance

Poor cabinet space and capacity planning and management

Unable to carry out remote monitoring and very tough to perform O&M and management

High O&M labor cost and low operation efficiency

Overview

Concepts: smart cabinet+smart module+centralized management platform (improving intelligent management level)

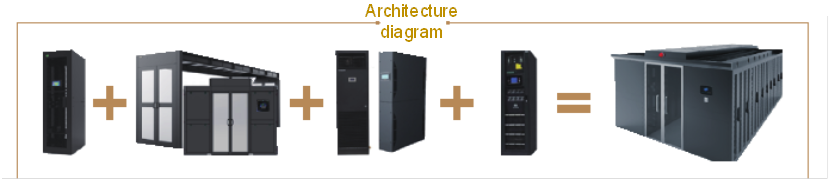

Product form: smart cabinet+cold channel+in-row air conditioners +precision distribution cabinet=smart data center with micromodule (achieving unified planning for all products and modular concept)

All subsystems such as cabinet, power supply and distribution, cooling, wiring and management are highly integrated. Flexible deployment of single-row or double-row airtight cold/hot channel is supported. (Flexible deployment and short construction period)

Highlights

Safety and reliability

◆ Monitoring distribution, UPS and air conditioning, safe and reliable electricity

◆ Equipping a manual bypass for UPS to avoid electrical accidents resulting from misoperation

◆ Temperature early warning and alarm in modules, and linkage of firefighting equipment

◆ Cold channel, level-2 security in cabinet, and effective guarantee for security of equipment room

Efficient cooling

◆ Optimizing cold channel air distribution method, and improving cooling effect of air conditioner

◆ In-row precision inverter air conditioner, intelligent linkage of cooling equipment

◆ Constant temperature and humidity for safeguarding efficient operation of system

Rapid deployment

◆ Integrated design, shortened construction period, and reduced construction cost

◆ Factory prefabrication, rapid site assembly, and saving time and efforts for installation

◆ Standard components, construction according to demands, fast enough to match business demands

◆ Supporting relocation of main equipment to another office location

Intelligent management

◆ A number of sensors for all-around online monitoring in real time

◆ Centralized management, and unified management and maintenance

◆ Online checking for equipment, and real-time position tracking

◆ Rack space management and intelligent equipment maintenance

Typical cases

Background

The design solution of intelligent micromodule equipment room is applied to an equipment room in a new building of a financial enterprise. To improve intelligence level of the equipment room, the construction method of cold channel and micromodule is used. By adding an intelligent PDU, electrical safety and stable operation of the building are provided. In the meantime, an asset management system is used, providing means of intelligence to IT equipment management in the equipment room.

Benefits

Electricity monitoring

By virtue of intelligent PDU, electricity of each cabinet can be monitored online in real time, ensuring reliable electricity in equipment room and avoiding electricity safety problems resulting from electrical overload.

Asset management

By adding an asset management system, visual management is implemented to equipment in a cabinet, cabinet capacity management is optimized, online and offline management is coordinated, and intelligent maintenance for cabinet is implemented.

Cost reduction

Intelligent O&M management tools are used for dealing with simple faults remotely, therefore reducing manual routine inspection, and greatly reducing O&M management costs.

Efficient operation

By virtue of intelligent management tools, resource utilization rate is effectively improved. In the meantime, big data analysis and decision means are used for improving overall operation efficiency of equipment room.